Technical Support for Toll/Contract Manufacturing Customers

Slide title

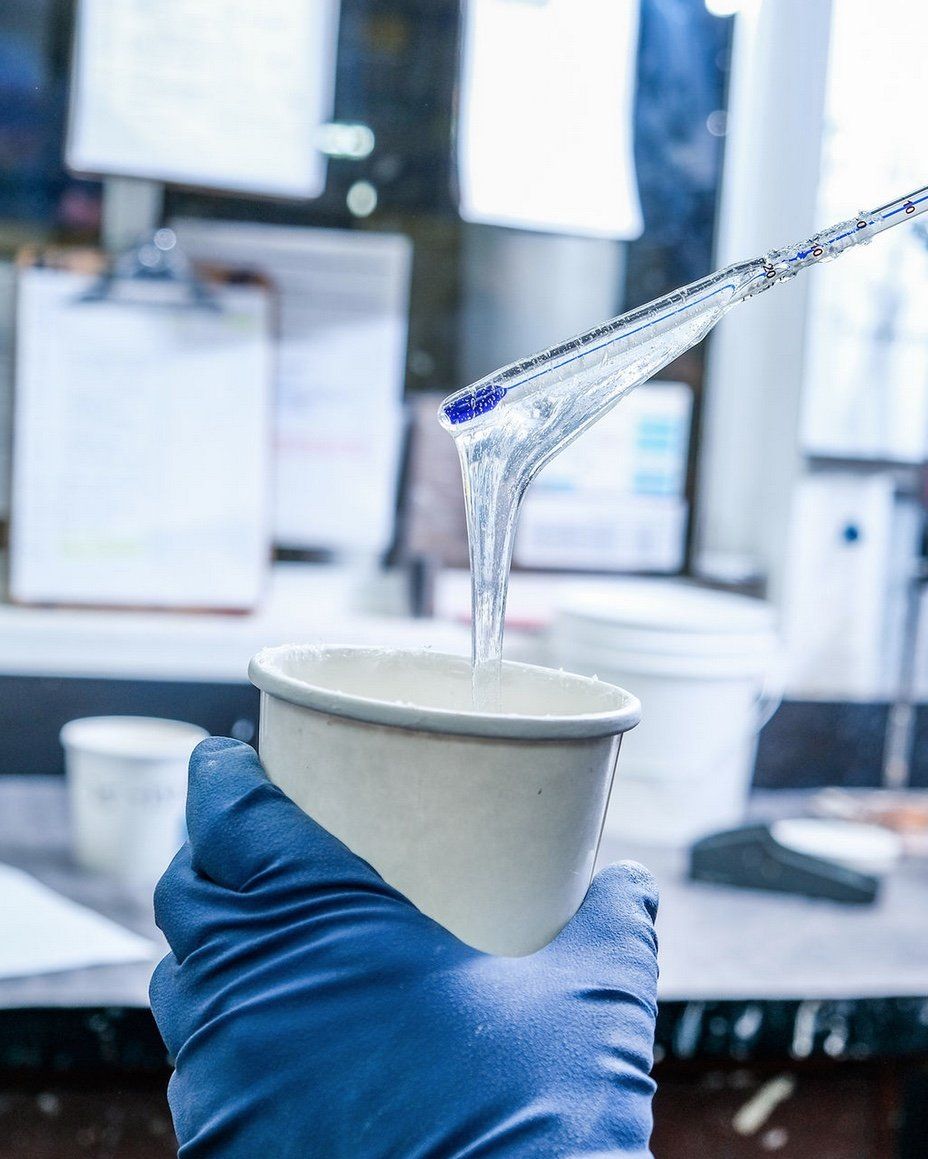

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

One of Camger’s greatest strengths is the depth of our industry and technical knowledge. Amongst our technical staff, we have decades of product and process engineering experience. While many of our toll manufacturing customers have their own technical departments, Camger can provide an added dimension of support with our onsite, boots on the ground, experts. Whether it be quality control or as involved as root cause analysis with corrective action determination, both certified as part of our ISO 9001 Quality Management System, we can help!

Our testing capabilities span a variety of physical property and performance categories pertinent to coatings applications. While we don’t use test methodologies for contract-based new product development, these capabilities do help with aforementioned quality assurance, root cause analysis, and even with expanding characterization of your existing products for increased marketability. The majority of our testing capabilities are performed via ASTM industry standards. Further, Camger’s technical experts in collaboration with our customer service department can provide your business with technical support to address product related issues that may arise in the field, with your customers.

See below for a brief table illustrating our technical capabilities as well as features we don’t offer:

| Category | Capability | Available? |

|---|---|---|

| Quality Assurance | Finished product Quality Control testing In process Quality Control testing Quality program design guidance [for your new products] Certificate of Analysis (CoA) generation Batch procedure accountability documentation |

√ √ √ √ √ |

| Contract Development | Contract new

product development Contract new process development |

X X |

| Physical Property Testing | Viscosity measurements [Brookfield, KU, Zahn, Ford] pH meter Gloss Color Spectrophotometry Density measurements % Solids measurements Flash Point measurements Ohm meter – electrical resistance measurements |

√ √ √ √ √ √ √ √ |

| Basic Material Analysis | Hegman Gauge - Particle Size Determination FTIR Spectrophotometry Digital microscopy |

√ √ √ |

| Advanced Analysis | GC, TGA, DSC, Mass Spec, XRD, AFM, SEM, etc. |

X |

| Performance Testing | Adhesion measurements [crosshatch, pull off] Mechanical durability measurements [abrasion, hardness, & scratch testing] Flexibility measurements [Impact testing, Mandrel Bend] Dry time measurements QUV testing / analysis |

√ √ √ √ √ |

| Engineering Support | Root cause analysis for customer concerns Corrective action determination and implementation for customer concerns Basic product optimization guidance Basic process optimization guidance |

√ √ √ √ |

Camger’s focus on quality is number one. Quality has always been wonderful. Most important thing. We don’t want items coming back and with Camger that doesn’t happen.

- David, Specialty Paint Company

Contact Us

Contact Us

We will get back to you as soon as possible

Please try again later

Contact Us

Please complete the inquiry form below and a member of our team will follow-up with you.

Global Footer Form

We will get back to you as soon as possible

Please try again later

Main Office

364 Main Street

Norfolk, MA 02056

Phone:

508.528.5787

Copyright © 2022 Camger Coatings Systems, Inc.